Concrete technology has been used from time memorial in construction. Nearly all buildings, bridges, industrial parks, complex high rise buildings, concrete pavements, tunnels, flyovers and many other superstructures are constructed using this material.

Most construction sites are located in remote places or areas far from central or concrete batching plants. In other cases, poor loads, heavy traffic jams, congestion, high population and poor site condition limit the use of readymade concrete from batching plants. These plants require on site concrete mixtures.

Concrete Mixer Design

Concrete mixers are loaded with a mixture of sand, aggregate, cement, water and other binders which are mixed to produce a uniform mixture ready for construction. The type of machine depends on volume of work and site specific conditions. The drum mixing method is used in these machines. The equipment has a drum and a set of rotating blades inside. The blades are engineered to lift materials as the drum rotate and this drop to the bottom when it reaches the top. This cyclic process achieves a uniform mix.

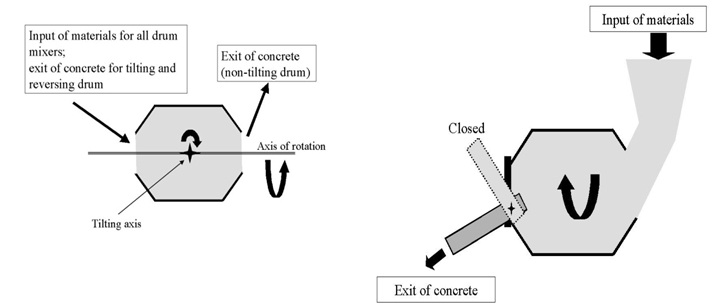

There are three common technologies in drum mixing: tilting, non-tilting and the reversing drum. The no tilting drum is fixed and materials are added at one end and discharged at the other. The tilting type allow for materials to be discharged by slanting the drum. The reversing type on the other hand rotates in one direction when mixing and the other when discharging.

Transit mixing trucks belong to the reversing type as the drum allows the charging, mixing and discharging.

The design of these mixers allows for uniform mixing and unloading. The speed of rotation and time are carefully controlled to guarantee uniformity of the mix. They are designed to operate with slump concrete which has high moisture and flow rates. These have very low operation and maintenance cost and are designed for construction market. They are a must have machine for all building and construction contractors.

Advanced Self Loading Concrete Mixtures

Most construction sites cannot access the service of batching plants; therefore, self loading concrete mixers are used. These machines are designed to measure the required amount of cement, sand and aggregate; load this to the drum, mix and unload ready concrete.

The process greatly simplifies the concrete work operation and eliminates labor intensive and costly loading and unloading processes. The machine is able to pick the required amount and this ensures right quantity as opposed to filling the drum manually. By utilizing advanced steering mechanism such as skid steer, the truck can turn through a small space and hence easily maneuverable. The truck is engineered to operate on rough rugged roads, tilted elevations and can climb high inclined surfaces. Other advantages include, hydraulic operation that saves fuel and ability to discharge concrete at require points.

Small Concrete Mixers

Small concrete mixtures are ideal for small construction sites. They mix materials and discharge them mainly be tilting. They are advantageous in remote construction sites as compared to hand mixing.

Self Loading Dumper

Self Loading Dumper is a specialized trucks used to load materials, transport them and unload them. They are very useful in transportation of materials such as concrete, cement and sand within the site. The truck operates efficiently in rough roads prevalent in most sites.

Recent Articles

- Market Growth and Future Trends in Self-Loading Concrete Mixers for the Construction Industry

- How Self-Loading Concrete Mixers Reduce Labour Costs and Increase Productivity?

- Comparing Self-Loading Concrete Mixers vs. Traditional Concrete Mixing Methods

- The Role of Self-Loading Concrete Mixers in Modern Construction

- Self-Loading Concrete Mixer Machines for Infrastructure Development Projects

Copyright © 2025, Apollo Carmix Equipments Private Limited (ACEPL), All rights are reserved.

Web Design & SEO by Webmasterindia